Your location:Home > Information dynamic

> News center

What are the general test dimensions of automobile inspection tools

Source:English website Release time:2020/3/24 14:29:26

What are the general test dimensions of automobile inspection tools

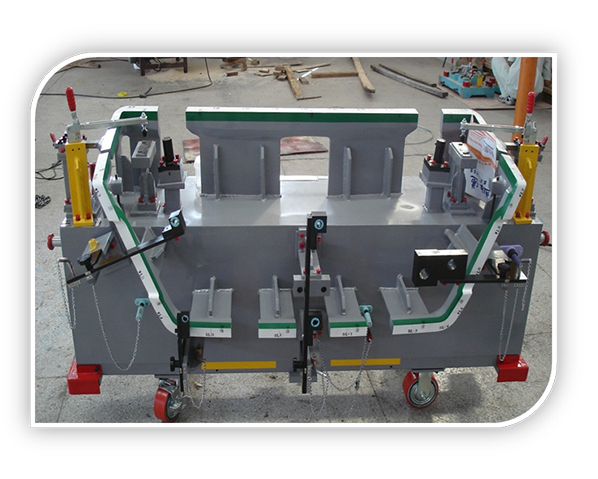

As the name implies, automobile inspection tools are specially designed by automobile manufacturers for convenient control of mechanical dimensions of auto parts, improvement of production efficiency and mass production of products. Generally speaking, it's like a ruler used to test whether a car product is qualified. So, what is the general test size for automobile inspection tools?

Generally, the locating pin, detecting pin and marking pin are used to control the important holes of automobile products. The positioning pin, inspection pin and marking pin all need to design the guide hole on the inspection tool as the benchmark to ensure that the pin is concentric with the product hole, and position the product on the inspection tool according to the GD & T drawing provided by the customer. The locating pin plays the role of locating tool, which has practical significance only when the product does not shake. The detection pin is used to detect whether the position of the important holes of the product is offset. The marking pin is used to mark out the product hole, visually check whether the marked line is concentric with the product, and whether the position of the hole is offset, generally used for sheet metal products.

Generally, clearance go no go gauge is used to control the important surface and edge of automobile products. Generally, the clearance surface of the vehicle inspection tool shall be 3mm or 5mm from the product. When testing, use go no go gauge to plug into the gap. When the go end can pass and the stop end can't pass, the product surface is qualified; otherwise, the product surface is unqualified. The go / no go gauge shall be designed according to the tolerance of the product surface and the gap between the inspection surface and the product. If the tolerance of surface contour is + / -0.5, the go / no go gauge of 3mm clearance shall be designed as go Ф 2.5-nogo Ф 3.5. When the tolerance of the surface contour changes to + / -0.3 and the clearance changes to 5mm, the go / no go gauge needs to change to go Ф 4.7-nogo Ф 5.3 accordingly.

Generally, the hole diameter go no go gauge is used to control the size of the important hole diameter of the product. The hole diameter go / no go gauge is designed according to the upper and lower limits of the product hole. The hole diameter go / no go gauge can be used independently without positioning. Insert the hole diameter go / no go gauge into the product hole. When the go end can pass and the no go end can not pass, the product hole diameter size is qualified; otherwise, the product hole diameter size is unqualified.

As the name implies, automobile inspection tools are specially designed by automobile manufacturers for convenient control of mechanical dimensions of auto parts, improvement of production efficiency and mass production of products. Generally speaking, it's like a ruler used to test whether a car product is qualified. So, what is the general test size for automobile inspection tools?

Generally, the locating pin, detecting pin and marking pin are used to control the important holes of automobile products. The positioning pin, inspection pin and marking pin all need to design the guide hole on the inspection tool as the benchmark to ensure that the pin is concentric with the product hole, and position the product on the inspection tool according to the GD & T drawing provided by the customer. The locating pin plays the role of locating tool, which has practical significance only when the product does not shake. The detection pin is used to detect whether the position of the important holes of the product is offset. The marking pin is used to mark out the product hole, visually check whether the marked line is concentric with the product, and whether the position of the hole is offset, generally used for sheet metal products.

Generally, clearance go no go gauge is used to control the important surface and edge of automobile products. Generally, the clearance surface of the vehicle inspection tool shall be 3mm or 5mm from the product. When testing, use go no go gauge to plug into the gap. When the go end can pass and the stop end can't pass, the product surface is qualified; otherwise, the product surface is unqualified. The go / no go gauge shall be designed according to the tolerance of the product surface and the gap between the inspection surface and the product. If the tolerance of surface contour is + / -0.5, the go / no go gauge of 3mm clearance shall be designed as go Ф 2.5-nogo Ф 3.5. When the tolerance of the surface contour changes to + / -0.3 and the clearance changes to 5mm, the go / no go gauge needs to change to go Ф 4.7-nogo Ф 5.3 accordingly.

Generally, the hole diameter go no go gauge is used to control the size of the important hole diameter of the product. The hole diameter go / no go gauge is designed according to the upper and lower limits of the product hole. The hole diameter go / no go gauge can be used independently without positioning. Insert the hole diameter go / no go gauge into the product hole. When the go end can pass and the no go end can not pass, the product hole diameter size is qualified; otherwise, the product hole diameter size is unqualified.