Your location:Home > Information dynamic

> News center

What is the standard formula for the size of the car inspection pin?

Source:English website Release time:2020/3/24 14:28:23

What is the standard formula for the size of the car inspection pin?

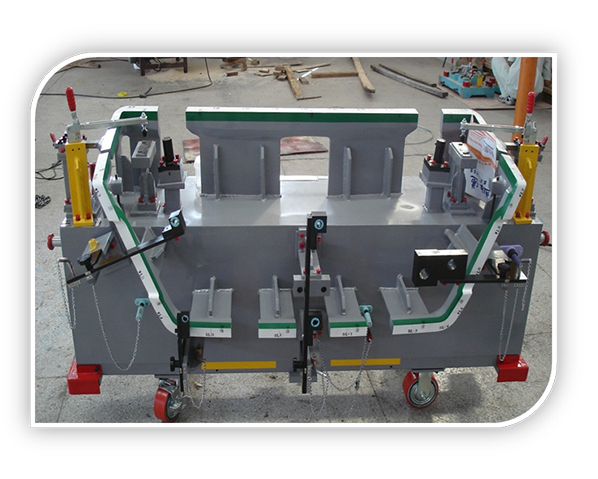

The inspection items of automobile inspection tool include three major points, namely: face inspection, edge (tangent) inspection and hole inspection.

Today, Shenzhen Xintai precision inspection tool company introduces the inspection of the lower hole to you. What is the standard formula for the size of the auto inspection tool pin?

There are two kinds of hole routine inspection: 1. Use inspection pin to inspect 2. Use marking to inspect. We have talked about the hole location marking detection in the past, so we will not repeat it here.

Inspection pin inspection hole position principle: generally, the position degree of product hole relative to benchmark will be marked on GD & T diagram,

For example, as shown in the figure below, the position degree of the hole is 0.5, which is the displacement of the hole relative to the datum

The deviation is + / -0.25, that is to say, the allowable max error relative to the benchmark in the process of product hole forming is + / -0.25. The position degree of the hole controlled on our inspection tool cannot exceed + / -0.25. The control method on the inspection tool is to design a inspection pin. The calculation formula of pin size is: aperture position degree. The gap between the inspection pin and the product is the tolerance on GD & T 。 When the hole position of the product exceeds the tolerance on the drawing, our inspection pin can not be inserted, so we use whether the pin can pass through the product hole as the standard to judge whether the hole position of the product is qualified.

There are two kinds of standard formulas for the size of automobile inspection pin: 1. Aperture position degree 2. Aperture position degree lower tolerance

Why there are two kinds of formulas, and how to choose them in our daily design process.

The inspection items of automobile inspection tool include three major points, namely: face inspection, edge (tangent) inspection and hole inspection.

Today, Shenzhen Xintai precision inspection tool company introduces the inspection of the lower hole to you. What is the standard formula for the size of the auto inspection tool pin?

There are two kinds of hole routine inspection: 1. Use inspection pin to inspect 2. Use marking to inspect. We have talked about the hole location marking detection in the past, so we will not repeat it here.

Inspection pin inspection hole position principle: generally, the position degree of product hole relative to benchmark will be marked on GD & T diagram,

For example, as shown in the figure below, the position degree of the hole is 0.5, which is the displacement of the hole relative to the datum

The deviation is + / -0.25, that is to say, the allowable max error relative to the benchmark in the process of product hole forming is + / -0.25. The position degree of the hole controlled on our inspection tool cannot exceed + / -0.25. The control method on the inspection tool is to design a inspection pin. The calculation formula of pin size is: aperture position degree. The gap between the inspection pin and the product is the tolerance on GD & T 。 When the hole position of the product exceeds the tolerance on the drawing, our inspection pin can not be inserted, so we use whether the pin can pass through the product hole as the standard to judge whether the hole position of the product is qualified.

There are two kinds of standard formulas for the size of automobile inspection pin: 1. Aperture position degree 2. Aperture position degree lower tolerance

Why there are two kinds of formulas, and how to choose them in our daily design process.