Your location:Home > Information dynamic

> News center

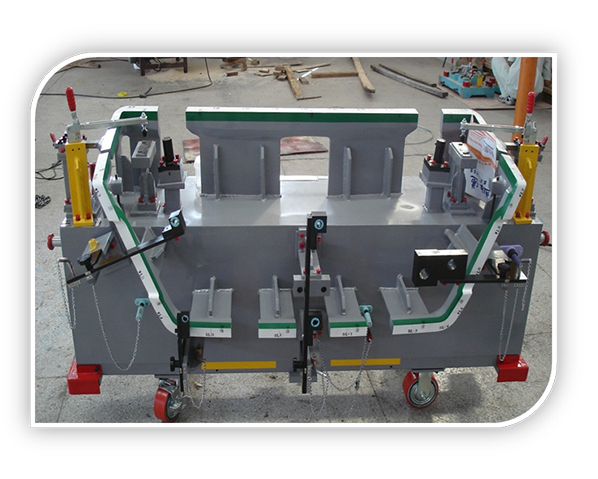

The importance of tempering of checking tool iron frame

Source:English website Release time:2020/3/24 14:34:00

As a basic support, the inspection fixture iron frame is responsible for the overall structural weight of the inspection fixture. In order to ensure the accuracy and durability of the inspection fixture, in addition to the necessary maintenance of the inspection fixture, the inspection fixture iron frame must be equipped with various deformation prevention strategies in advance at the beginning of the inspection fixture processing to ensure that the iron frame will not deform in the long-term use process.

Take Xintai precision inspection tool as an example, to complete a basic iron frame, first cut the square tube or cut it into a length that meets the requirements of 2D size, and then drill the vent hole on the drilling machine, in order to let the heated expansion gas discharge from the vent hole in the process of tempering to avoid deformation of the square tube support. After the completion of welding into an iron frame, remove the welding slag and send it to tempering. Tempering refers to the process of heating the workpiece to a proper temperature lower than the critical temperature, and cooling it in air, water, oil and other media after holding for a period of time. Used to reduce or eliminate internal stress caused by welding. The common tempering processes are martensite decomposition, carbide precipitation, transformation, aggregation, ferrite recovery and recrystallization.

Take Xintai precision inspection tool as an example, to complete a basic iron frame, first cut the square tube or cut it into a length that meets the requirements of 2D size, and then drill the vent hole on the drilling machine, in order to let the heated expansion gas discharge from the vent hole in the process of tempering to avoid deformation of the square tube support. After the completion of welding into an iron frame, remove the welding slag and send it to tempering. Tempering refers to the process of heating the workpiece to a proper temperature lower than the critical temperature, and cooling it in air, water, oil and other media after holding for a period of time. Used to reduce or eliminate internal stress caused by welding. The common tempering processes are martensite decomposition, carbide precipitation, transformation, aggregation, ferrite recovery and recrystallization.